Ceramics in the Space Industry

The use of technical ceramics in the space industry will often be likened in the public mind to the ceramic tiles used to coat the underside of each of the USA’s Space Shuttles, at the time defined as a three-dimensional jigsaw the size of a football pitch. This however is a small part of the uses and applications for these hi-tech materials.

With the ever-growing realisation that space-based systems for communication, science, earth observance, military and commerce are the way forward, the expansion of satellites crowding the low and medium earth orbits have leapt from under 2000 in 1999 to an estimated figure approaching 20,000 in 2024.

This race to space has driven technology and cost as the numbers increase and more commercial companies enter the market and the designs, sizes and applications of these satellites opens the doors for more innovative thinking.

Precision Ceramics has been a major player in this developing technology for many years and have worked consistently with our partners to develop the latest propulsion and electrical insulation technology.

Satellite Technology

The explosion in satellite usage is driven by reductions in size and cost – both operational and build/launch cost enabling the latest technology to compete with earth bound solutions.

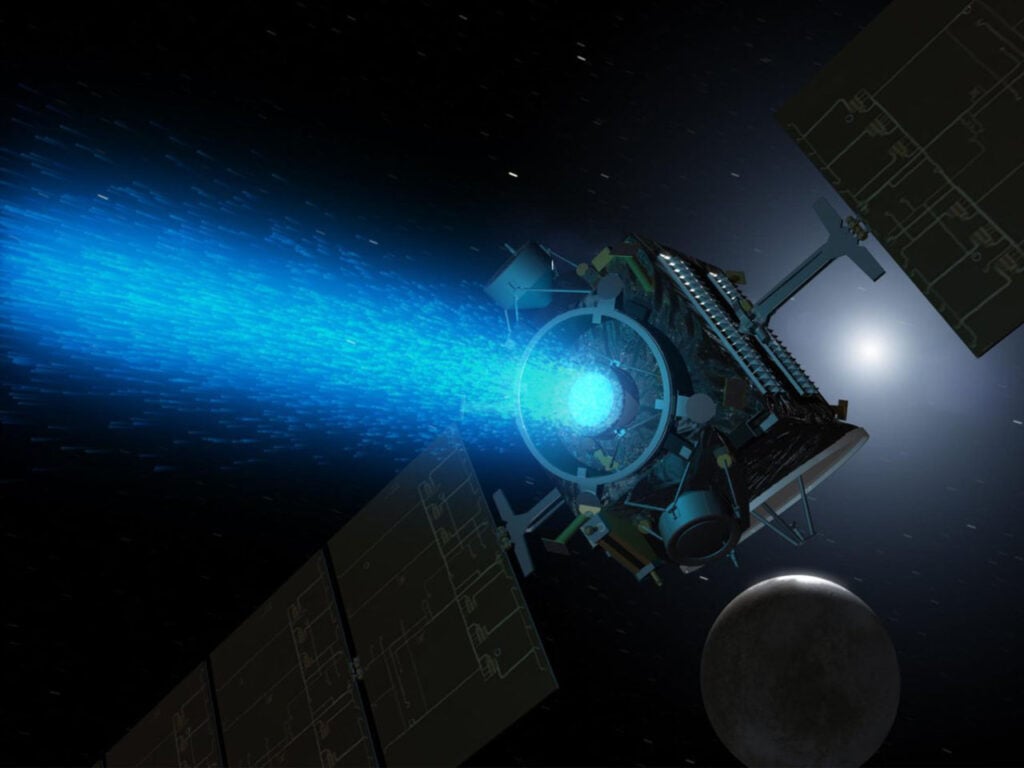

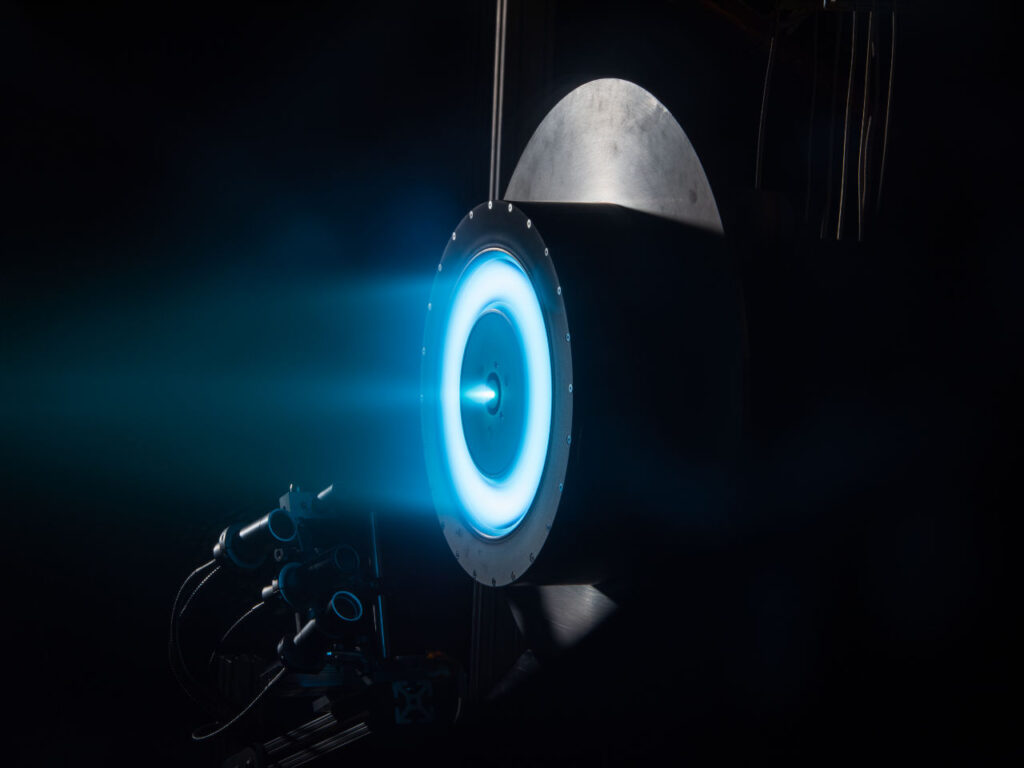

Ion Propulsion

Ceramic materials that are proven in ion propulsion technology include high purity Alumina and Shapal Hi-M Soft.

Hall Effect Thrusters

Hall effect thrusters use inert gases as the propellant, which removes the chance of accidental flammable explosion and satellite weight.