Which ceramic materials can be selected for low or high thermal conductivity and what are the values?

When we think about ceramic materials, our first instinct might be to assume there is always excellent ceramic thermal insulation. However, the reality is that engineering ceramics come with a wide range of thermal conductivities, with the lowest and highest values varying by 200-fold!

It’s important to note that ceramic electrical insulation and ceramic thermal insulation are independent of each other. So, you can choose an electrical insulator that’s also an excellent thermal conductor, which is very useful for electronic substrates that need to extract the heat from a device such as a mobile phone or laptop.

And, interestingly, the reverse is possible too, though this often achieved by coating metals with a good ceramic insulator.

Now, let’s dive into some of the ceramics that are commonly chosen for ceramic thermal insulation. We have Alumina, the Zirconia family of materials, various silicates like Cordierite, Steatite and Porcelain, and then there are the machinable ceramics such as Macor, and really high thermal conductivity ceramics such as Aluminium Nitride and Beryllium Oxide, known as Beryllia.

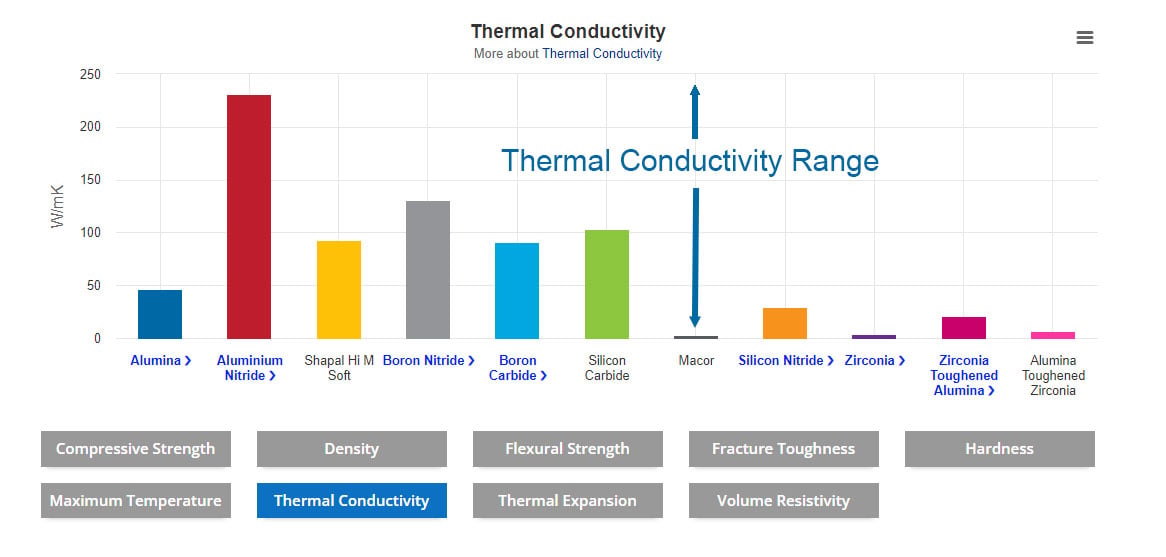

We measure thermal conductivity in units of Watts per meter Kelvin, and Macor, for instance, has a thermal conductivity of just 1.5. Silicate ceramics used for electrical insulation typically fall in the range of 2 to 4, whilst zirconia-based ceramics hover around 3. Alumina toughened zirconia goes up a bit to approximately 6 W/mK. Now, when you look at alumina-based ceramics, they’re in a different league, with values ranging from 25 to 40, whilst Shapal, another machinable ceramic, takes a significant leap to about 90 W/mK. Then, there are Aluminium Nitride ceramics, boasting values of roughly 170 to 220, and Beryllia with a remarkable 300 W/mK – as impressive as copper! Note, however, that Beryllia is rather toxic and so is generally only used by the military for substrates.

The reasons for these very different thermal conductivity values are well-documented and can be easily researched if needed – essentially, it comes down to how much the thermal vibrations (known as phonons) are disrupted by the crystal structure or microstructure.

Now, when it comes to thermal barrier materials, we have alternatives like plastics, glasses, some metals such as stainless steels, thermal barrier coatings, and fibre composite-based materials. The choice among these depends on the specific application and design requirements.

Factors like temperature range (which may rule out polymers and metals), the surrounding atmosphere (which might necessitate particular ceramics), and whether there will be mechanical loading or rapid temperature changes, amongst other considerations, all come into play.

Which applications may require thermal insulation properties?

You can discover more about materials guidance and find application examples on Precision Ceramics website’s materials pages. Some typical applications include high-power electronics, cryogenic systems, high-temperature processing, furnaces, jet engines and space applications such as heat insulation and electronic substrates in satellites, among many others.

The website offers comprehensive insights into how these materials play crucial roles in various industries and technologies.

Professor Jon Binner Precision Ceramics

Professor Jon Binner, esteemed academic at the University of Birmingham renowned for his contributions to the field of ceramics, has joined forces with Precision Ceramics to produce a series of enlightening explainer videos on advanced ceramic materials.

With a wealth of experience demonstrated through numerous peer-reviewed papers, edited books, and patents to his name, Professor Binner brings unparalleled expertise to the collaboration.

His longstanding relationship with Precision Ceramics underscores his commitment to advancing knowledge in the realm of ceramic materials. Thrilled to participate in a project aimed at educating and informing audiences about the intricacies of ceramics, Professor Binner’s involvement promises to offer valuable insights into this vital area of materials science.

Precision Ceramics is a leader in supplying customised technical ceramics solutions. We go beyond mere manufacturing – we partner with you at every stage of material selection, product design and development.

If you have any questions regarding which ceramic material might be best for your application, please don’t hesitiate to contact us.

Related topics:

Thermal Conductivity

Thermal conductivity measures how easily heat is transmitted through a material. There is a growing specialist market for advanced ceramics use in applications with high thermal conductivity requirements.

Ceramic Thermal Conductivity Blog

In this blog we compare the materials Boron Nitride, Boron Nitride composites, Beryllium oxide, and Aluminium Nitride for thermal conductivity ranges.

Materials

Precision Ceramics offers a wide range of advanced advanced ceramic materials to ensure that we have the right material for your application.