Macor glass ceramic is an outstanding engineering material and is machinable with ordinary metalworking tools. It is also a problem solving material combining the performance of a technical ceramic with the versatility of a high performance plastic.

Macor has a high use temperature (800°C continuous to 1,000°C peak). It has a low thermal conductivity and is a useful high temperature insulator as well as an excellent electrical insulator. Macor has no porosity and when properly baked out, will not outgas. It is strong and rigid and, unlike high temperature plastics, will not creep or deform. Macor is also radiation resistant.

Macor is pure white and can be highly polished. It can be thick or thin film metallised, brazed and epoxy bonded. Another major advantage of this unique material is that, even in small quantities, components are economical to manufacture. Another topic related to this covered in our Macor series is the Macor Brazing Guide.

Macor is now manufactured exclusively in France by Corning Incorporated and Precision Ceramics is the UK’s principal distributor for this unique machinable glass ceramic.

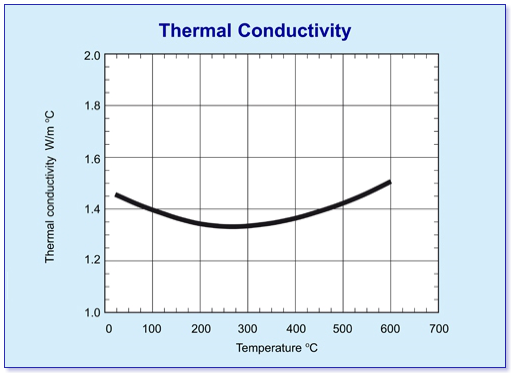

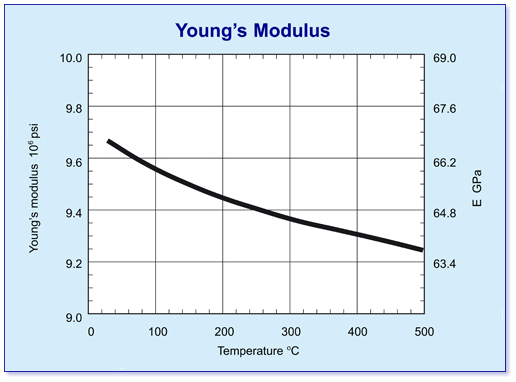

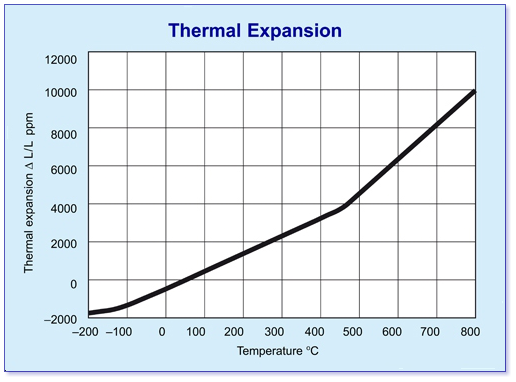

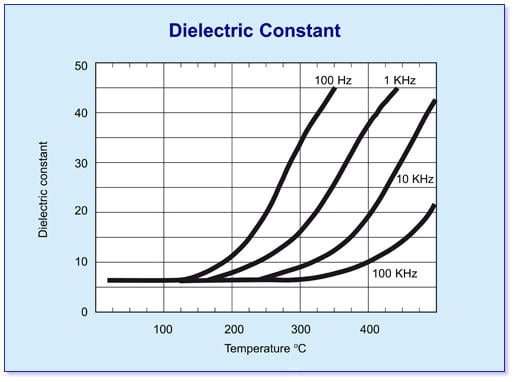

In this post we evaluate the following technical properties of Macor in the following graphs derived from laboratory tests performed by Corning on sample quantities. Actual characteristics of production lots may vary.

Thermal Conductivity

Young’s Modulus

Thermal Expansion

DC Volume Resistivity

Dielectric Constant

Modulus Of Rupture

Loss Tangent

Related Topics

Macor ®

Machinable Glass Ceramic

Macor is a hybrid glass-ceramic with the versatility of a high performance polymer, the machinability of a metal, and the performance of an advanced advanced ceramic.

Macor Brazing Guide

Macor is an outstanding engineering material and is machinable with ordinary metalworking tools. In this post we detail the brazing guide for Macor.