Ceramics for Fuel Cells

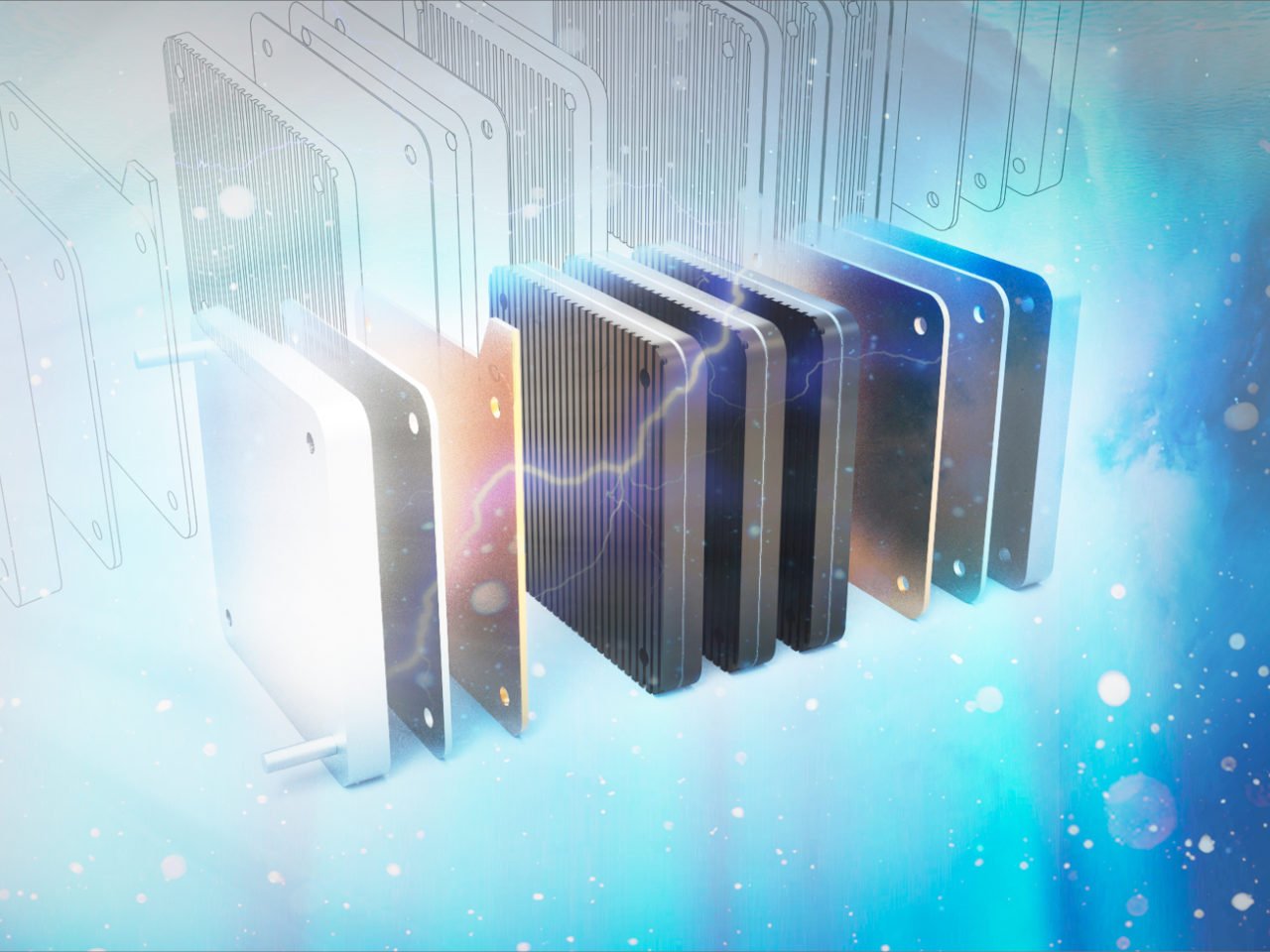

There are many types of Fuel Cells, but most follow the basic principle of creating an electrochemical cell that has a continuous fuel source supplied. Unlike a battery where the fuel is inbuilt and finite, the chemical energy (hydrogen for example) and oxidizing agent then create a continuous chemical reaction.

Positively charged hydrogen ions flow from the anode to the cathode through the electrolyte and a second direct current circuit flows from the anode to the cathode creating a circuit. A second reaction at the cathode creates water and other possible byproducts.

Many types of fuel cells exist using a wide range of fuels. SOFC (Solid Oxide Fuel Cells) run at high temperature with a ceramic electrolyte – typically 800°C to 1,100°C – and can operate continually at these temperatures in a highly efficient manner once they reach temperature.

High temperature fuel cells tend to have a greater working efficiency and be used in more commercial applications generating kW to mW capacity. The electrical requirements at elevated temperatures require Technical Ceramics and many are used in a range of roles including electrical insulation, thermal shielding, feedthrough, thermal conductors, thermal insulators, and chemical resistance.