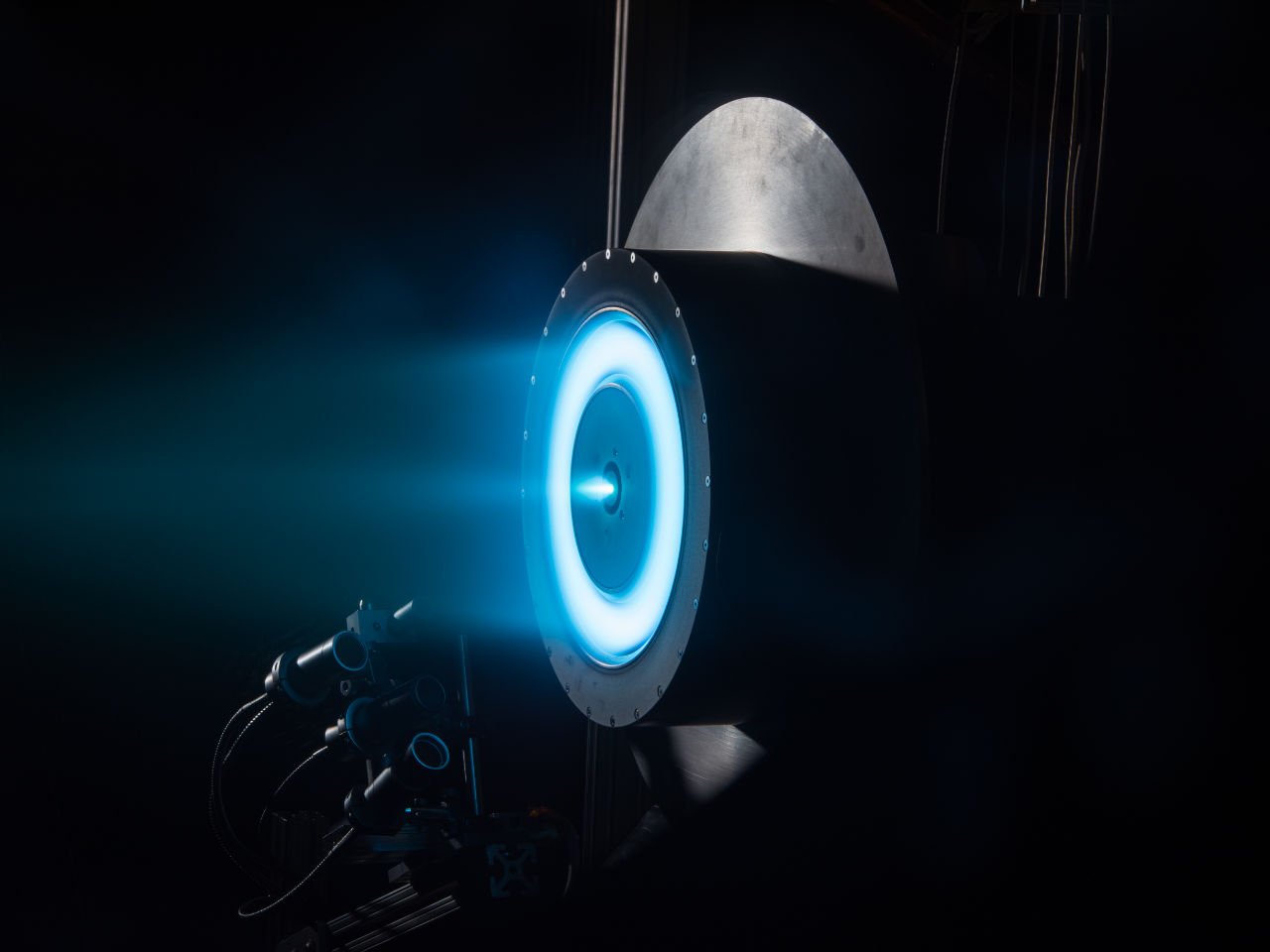

Ceramics for Hall Effect Thrusters

Materials for Hall Effect Thrusters

Shapal Hi M Soft

Machinable Aluminum Nitride

Shapal Hi M Soft electrically insulating, excellent at thermal shock, fully dense and an excellent thermal conductor.

Grade M26

Boron Nitride

Boron Nitride M26 has lower thermal conductivity and electrical insulation compared to Shapal Hi M Soft and AX05.

PCBN2000

Boron Nitride

PCBN2000 has excellent thermal shock resistance while delivering low thermal expansion. Easily machined and has good flexural strength.

Grade HP

Boron Nitride

HP is useful when low thermal expansion, high thermal shock resistance, and strong electrical properties are required.

Grade AX05

Boron Nitride

AX05 provides high resistivity and dielectric strength with a low loss tangent and dielectric constant.

Hall Effect Channel Material Selection

Ceramic selection for Hall Effect channels, requires a low weight material with excellent electrical insulation. The material must have consistent electrical/chemical/mechanical properties and be able to be machined into complex accurate geometries. Shapal Hi M Soft and the Boron Nitride grades have a proven track record and have been thoroughly tested by space agencies around the world. New grades of materials are constantly being added as price and availability can be factors that influence selection. Continuous evaluation of these materials ensures the best possible material offering.

The considerations for each of the material grades are as follows:

- Shapal Hi M Soft is an Aluminum Nitride/Boron Nitride composite. It is a very consistent homogeneous material, has excellent thermal conductivity and thermal shock resistance, is electrically insulating and fully dense. Being harder than the other materials, it allows fine features to be machined.

- M26 is a Boron Nitride/Silica composite. Made in very large billets to enable the largest Hall Effect Thruster channels to be produced. The material does not have the high thermal conductivity or the electrical insulation properties of Shapal Hi M soft or AX05, but is a lower cost alternative to both of these materials.

- AX05 is a binder-less grade of Boron Nitride, which has the lowest density of all the materials considered, but the material has porosity of over 20% to allow the binder to be removed during sintering. The binder removal can only be achieved with limited wall thicknesses. Therefore AX05 can only be produced in relatively small billets. The binder removal leaves a pure Boron Nitride with good electrical performance, but is weaker than the other material options.

- PCBN2000 is another Boron Nitride/Silica composite similar to M26, but with a slightly higher silica content.

- HP is a Boron Nitride with a calcium borate binder, made in large blanks for large channels. It’s used in a number of space based applications.

Material Properties

The below table compares the materials available at Precision Ceramics used in Hall Effect Thrusters and the relevant properties:

| Property | Unit | Shapal Hi M Soft | Grade M26 | PCBN2000 | Grade HP | Grade AX05 |

|---|---|---|---|---|---|---|

| Composition | – | AlN/BN composite | BN/Silica composite | BN/Silica composite | BN (calcium borate binder) | BN (binder-less grade) |

| Dielectric Strength |

kV/mm | 65 | 66 | – | >10 | 79 |

| Thermal Conductivity |

W/mK | 92 | 11 ∥ / 29 ⊥ | – | 27 ∥ / 29 ⊥ | 78 ∥ / 130 ⊥ |

| CTE 25°C ➞ 400°C |

10-6/K | 4.8 | 3.0 ∥ / 0.4 ⊥ | – | 0.6 ∥ / 0.4 ⊥ | -2.3 ∥ / -0.7 ⊥ |

Note: ∥ = Parallel and ⊥ = Perpendicular

Coefficient of Thermal Expansion (CTE) describes how the size of an object changes with a change in temperature.

Disclaimer: The values presented are mean and typical of those resulted from test samples. They are provided as an indication only to serve as guidance in the design of ceramic components and are not guaranteed in any way. The actual values can vary according to the shape and size of the envisioned component.

Datasheets

Shapal Hi M Soft

Machinable Aluminum Nitride

Boron Nitride

Grade M & M26

Boron Nitride

PCBN2000

Boron Nitride

Grade HP

Boron Nitride

Grade AX05

Other Ceramic Components Within Hall Effect Thrusters

Materials other than Boron Nitride and Shapal Hi M Soft can be used in other areas of the thruster where the demands are not as critical. Materials such as Macor and Alumina can also be used as electrical insulators, where they are not in contact with the ion plasma.

Alumina is used for its electrical and mechanical strengths and Macor for complex machined shapes. The lower costs of these materials keeps the affordability of the overall thruster competitive.