Alumina – CeramAloxTM

Advantages

- Excellent electrical insulation properties

- High hardness and mechanical strength

- Wear and abrasion resistant

- High thermal conductivity and thermal shock resistance

- Low density

- Resistant to strong acid and alkali attack at high temperatures

- Transparent to microwave radio frequencies

- High compressive and dielectric strength

- Very specific thermal conductive and thermal expansion rates

Applications

Alumina is a very hard ceramic that is excellent at resisting abrasion and is ideal for wear-resistant inserts or products. It is commonly used as a high temperature electrical insulator, particularly the higher purity grades which offer better resistivity. It also offers good resistance to strong acids and alkalis at elevated temperatures, which makes it ideal for applications where resistance to corrosive substances is required. Some common applications include:

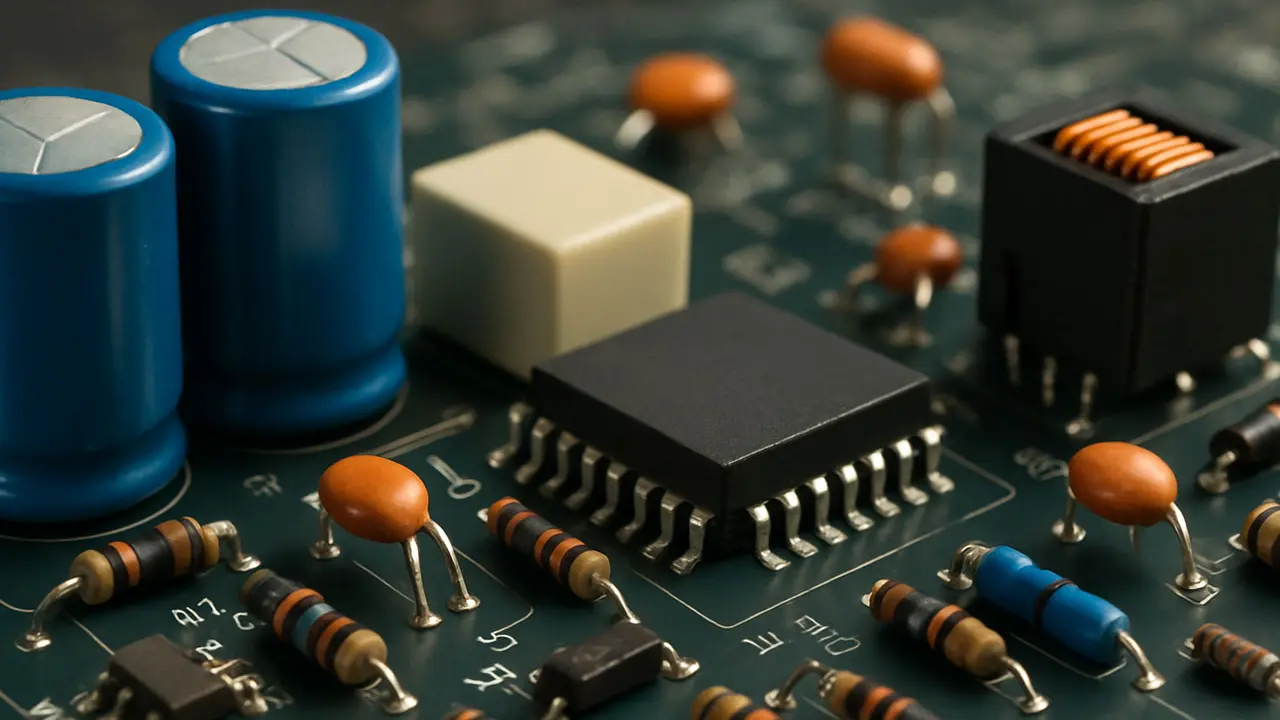

- Electronic Components

- High Temperature Insulators

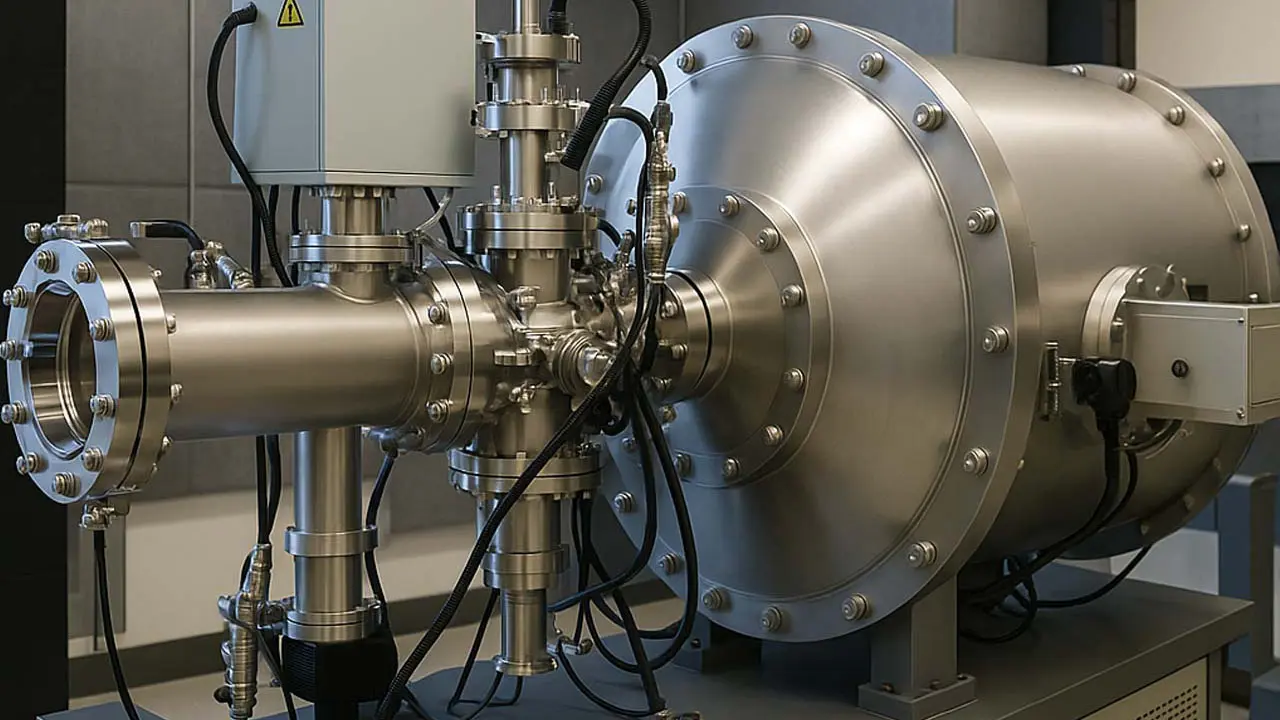

- Surface Science Components

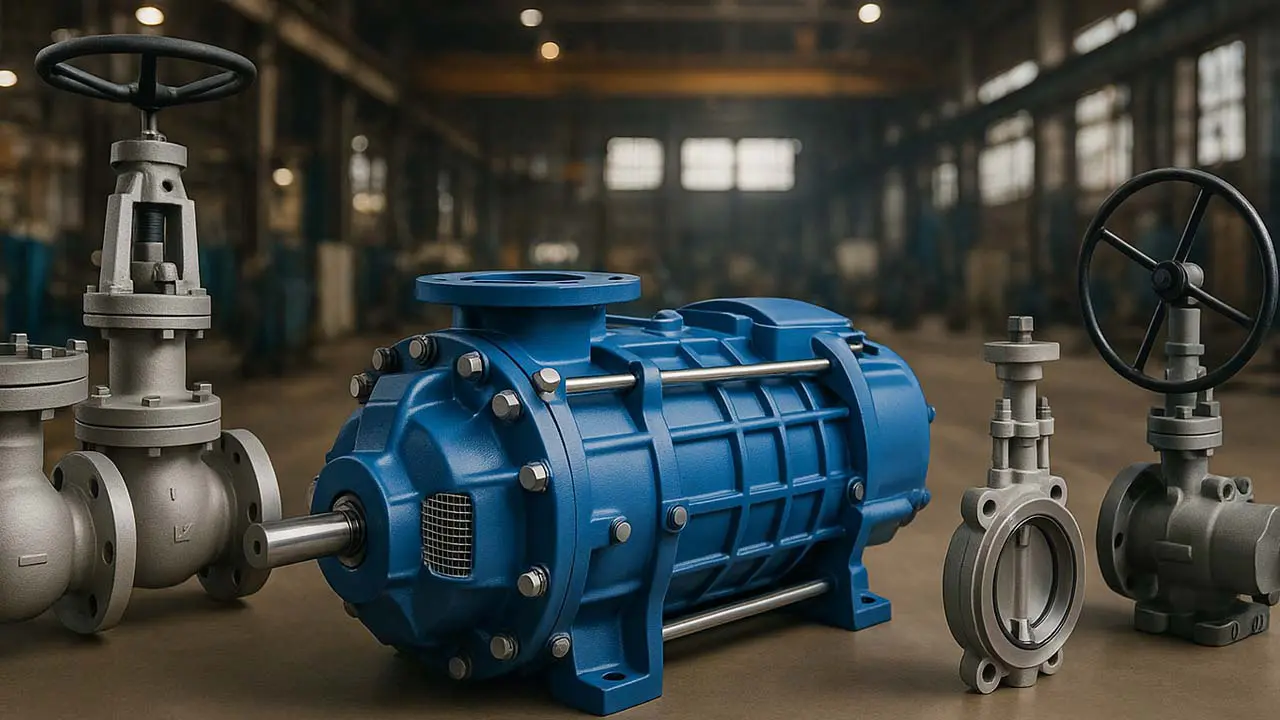

- Pistons and Sleeves

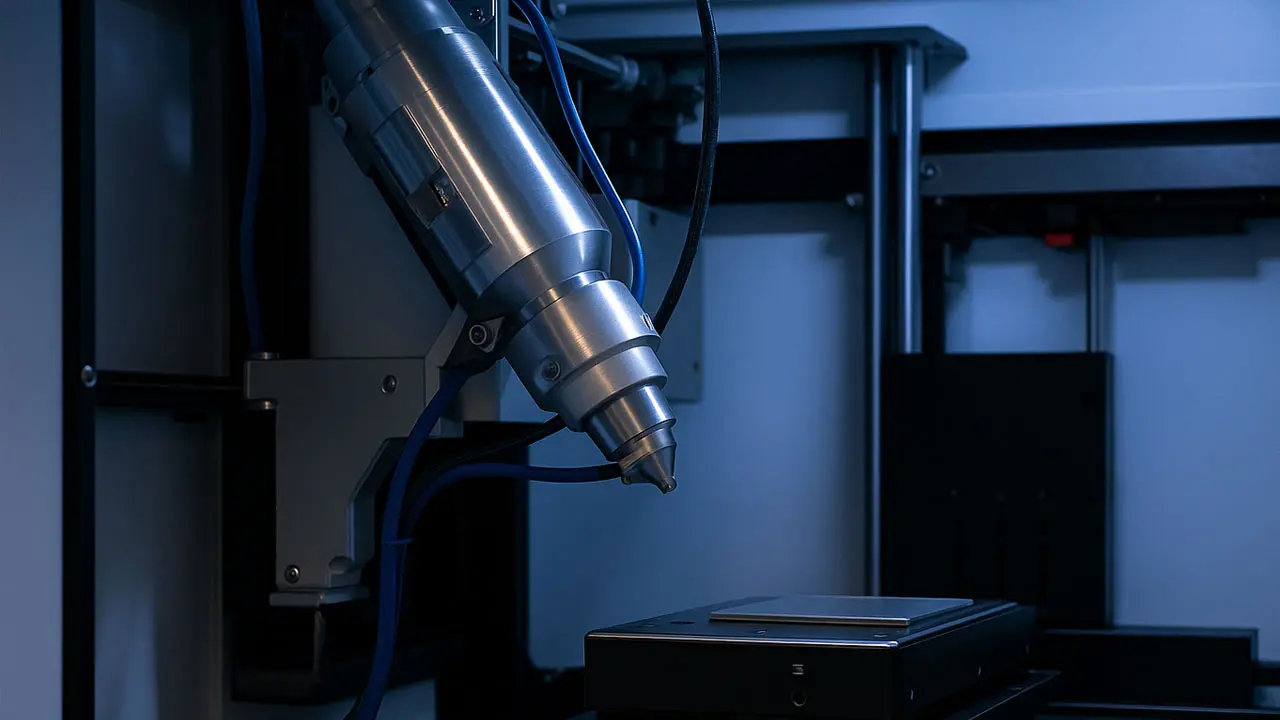

- Semiconductor Processing

- Wear Components

- High Voltage Components

Alumina Material Grades

Precision Ceramics has three variations of Alumina which are CeramAlox Ultra Pure, CeramAlox 99.7 and CeramAlox 96. The differing methods used to produce these materials resulted in slightly different properties and characteristics. We evaluate the similarities, differences and properties of each material and it’s applications in this section.

CeramAlox 96

Overview

CeramAlox 96 is a regular purity grade Alumina (Aluminum Oxide) and its one of the workhorses of the technical ceramics industry. It features a 96% purity Alumina base material providing a balanced “cost to quality” ratio. It is a hard-wearing technical ceramic offering an excellent combination of both mechanical and electrical properties and is ideally suited to a wide range of industrial applications where cost is of the essence, but the material still needs to perform adequately from a mechanical and electrical standpoint.

CeramAlox 96 can be machined in the “green state”- that is before sintering takes place, thus ensuring a large variety of shapes and sizes. CeramAlox 96 can also be diamond ground to tight tolerances in the fully sintered state using diamond grinding.

Applications

- Electronic components & substrates

- High temperature electrical insulators

- High voltage insulators

- Laser tubes

- Machined components

- Mechanical seals

- Precision shafts and axles in high wear environments

- Roller and ball bearings

- Seal rings

- Semiconductor parts

- Shot blast nozzles

- Thermocouple tubes

- Tap plates

- Valve seats

- Wear components

- Wire and thread guides

- Ballistic Armor

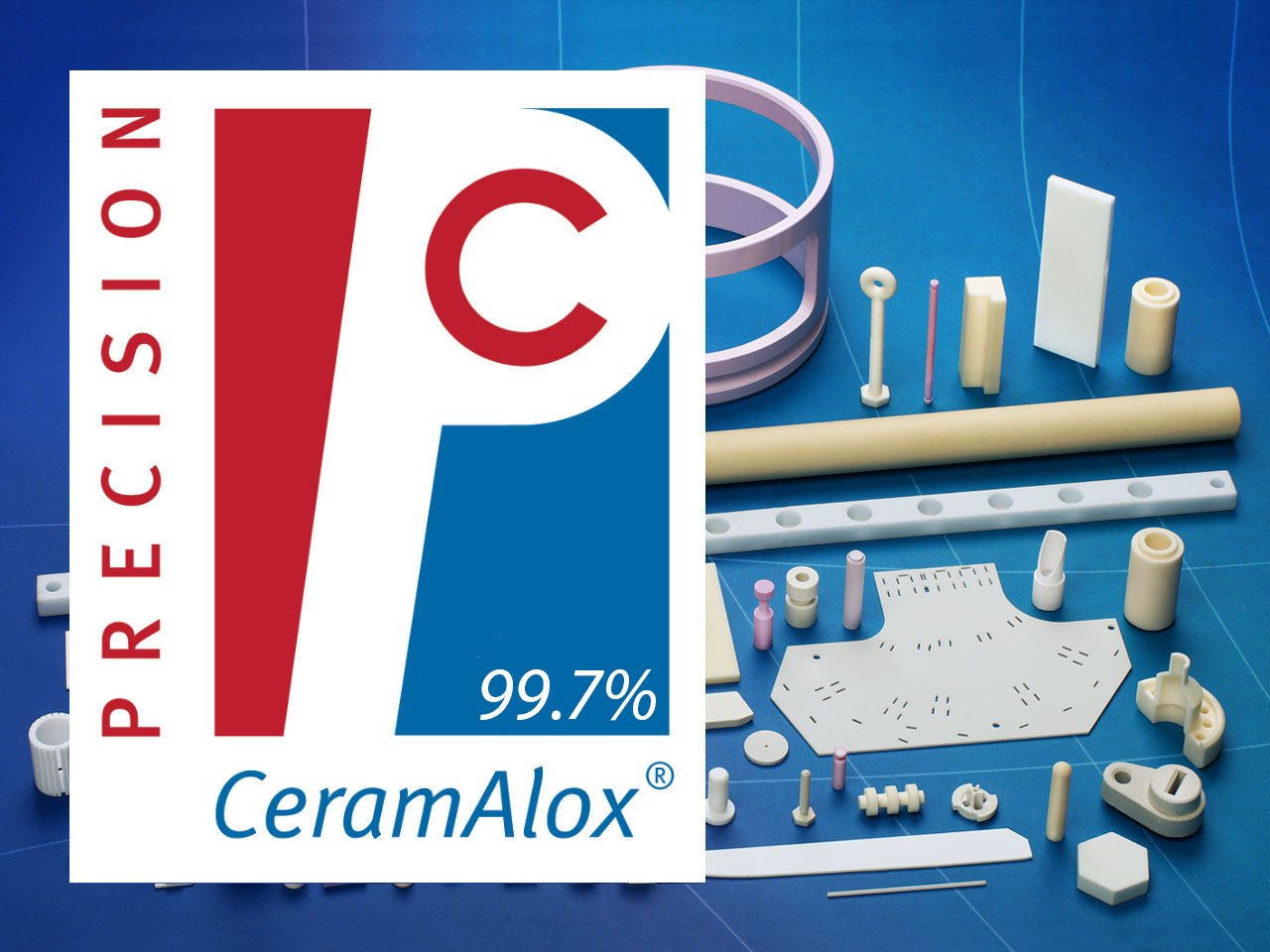

CeramAlox 99.7

Overview

CeramAlox 99.7 it’s a high purity grade Alumina (Aluminum Oxide) and its one of the high performance grades in this range of materials. It features a 99.7% purity Alumina base material providing a superior set of mechanical and electrical properties while maintaining a reasonable cost. CeramAlox 99.7% is a very hard-wearing technical ceramic offering and is ideally suited to a wide range of industrial applications where mechanical and electrical performance is of the essence and the material needs to perform adequately in aggressive environments.

CeramAlox 99.7 can be machined in the “green state”- that is before sintering takes place, thus ensuring a large variety of shapes and sizes. CeramAlox 96 can also be diamond ground to tight tolerances in the fully sintered state using diamond grinding.

Applications

- Electronic components & substrates

- High temperature electrical insulators

- High voltage insulators

- Laser tubes

- Machined components

- Mechanical seals

- Precision shafts and axles in high wear environments

- Roller and ball bearings

- Seal rings

- Semiconductor parts

- Shot blast nozzles

- Thermocouple tubes

- Tap plates

- Valve seats

- Wear components

- Wire and thread guides

- Ballistic Armor

CeramAlox 99.95 Ultra Pure

Overview

CeramaAlox Ultra Pure is a very high purity (99.95%) grade of Alumina (Aluminum Oxide) exhibiting an exceptional combination of mechanical and electrical properties. It features very high hardness, exceptional electrical resistivity, high temperature mechanical stability and strength in addition to corrosion resistance and bio/chemical inertness.

Its high temperature stability and electrical stability make it particularly suitable for high temperature applications such as high voltage/frequency insulators, heating elements supports, etc.

Applications

- High temperature electrical insulators

- Very high voltage/frequency insulators

- Machine components where high wear resistance

is required in an oxidizing environment - Precision shafts in high wear condition

- Unlubricated (vacuum) or gas/water lubricated

high speed sliding bearings - Shot blast nozzles

- Abrasive flow deflector plates/cones

- Valve seats

- Wire guides

Alumina Material Properties

Mechanical Properties

| Property | Unit | 96% | 99.7% | 99.95% |

|---|---|---|---|---|

| Density | g/cm3 | 3.75 | 3.95 | 3.98 |

| Compressive Strength | MPa | 2000 | 2000 | 3500 |

| Tensile Strength | MPa | 140 | 150 | 200 |

| Flexural Strength @ 25°C |

MPa | 200-300 | 250-350 | 500-600 |

| Fracture Toughness KIC |

MPa m1/2 | 4.5 | 4 | 4.5 |

| Hardness |

GPa | 12 | 14 | 18 |

| Young’s Modulus |

GPa | 300 | 370 | 400 |

| Poisson’s Ratio |

– | 0.23 | 0.23 | 0.23 |

Thermal Properties

| Property | Unit | 96% | 99.7% | 99.95% |

|---|---|---|---|---|

| Thermal Conductivity @ 25°C | W/mK | 25 | 33 | 45 |

| Thermal Shock | – | Good | Good | Good |

| CTE1 25°C ➞ 300°C | 10-6/K | 6.3 | 6.5 | 7.5 |

| CTE1 25°C ➞ 700°C | 10-6/K | 7.0 | 7.5 | 8.0 |

| Maximum Temperature (Inert) 2 | °C | 1600 | 1700 | 1750 |

* Coefficient of Thermal Expansion (CTE) describes how the size of an object changes with a change in temperature.

** Note: No load

Electrical Properties

| Property | Unit | 96% | 99.7% | 99.95% |

|---|---|---|---|---|

| Dielectric Constant @ 1 MHz | – | 9.8 | 9.9 | 9.9 |

| Dielectric Constant @ 10MHz | – | 9.6 | 9.7 | 9.7 |

| Dielectric Strength DC @ 25°C | kV/mm | 9 | 11 | 16 |

| Dielectric Loss | 1 MHz | 0.0001 | 0.0001 | 0.0001 |

| Volume Resistivity @ 25°C | ohm-cm | >1014 | >1014 | >1016 |

Disclaimer: The values presented are mean and typical of those resulted from test samples. They are provided as an indication only to serve as guidance in the design of ceramic components and are not guaranteed in any way. The actual values can vary according to the shape and size of the envisioned component.

Datasheets

Alumina

All Grades CeramAlox

Alumina

96% CeramAlox

Alumina

99.7% CeramAlox

Alumina

99.95% CeramAlox Ultra Pure

Alumina Machining

Alumina can be produced in a wide range of purities with additives designed to enhance its properties. Typical purities range from 90 to 99.9% although Precision Ceramics generally works with 99.7% material.

It can be injection molded, die pressed, isostatically pressed, slip cast, and extruded. Once fired and sintered, it can only be machined using diamond grinding methods. Advanced green and biscuit machining techniques developed by Precision Ceramics allow more complex components to be manufactured using traditional machining methods. In addition, Alumina can be readily joined to metals or other ceramics using metalizing and brazing techniques.

Alumina can be machined in green, biscuit, or fully dense states. While in the green or biscuit form, it can be machined relatively easily into complex geometries. However, the sintering process that is required to fully densify the material causes the alumina body to shrink approximately 20%. This shrinkage means that it is impossible to hold very tight tolerances when machining alumina pre-sintering. In order to achieve very tight tolerances, the fully sintered material must be machined/ground with diamond tools. In this manufacturing process, a very precise diamond coated tool/wheel is used to abrade away the material until the desired form is created. Due to the inherit toughness and hardness of the material, this can be a time consuming and costly process.

Precision Ceramics specializes in tight tolerance and highly complex work. We have extensive in-house machining facilities, including 4th & 5th axis machining centers, drilling, grinding, milling, polishing, sawing, tapping, threading and turning. This allows us to manufacture Alumina components to the highest specifications.

Precision Ceramics is your Alumina machining specialist for all your technical ceramic prototyping & manufacturing needs. We are always happy to use our many years of advanced ceramics experience to provide advice on materials, design, and application. If you would like to buy Alumina plates, rods, tubes or custom machined components, please contact us and one of our experts will be happy to assist you.

CeramAlloy Ultra Hard

Alumina-Zirconia (ZTA) ceramic composites are unique ceramic materials that exhibit a combination of high hardness, strength, wear and corrosion resistance characteristics compared to their alumina component. All this while still maintaining reasonably high fracture toughness specific to its zirconia component. In this video, we test and show the wear characteristics of CeramAlloy Ultra Hard.

Frequently Asked Questions

-

What's the difference between Macor and Alumina?

Alumina is a very commonly used technical ceramic due to its versatile properties, however, because it is such a hard material extensive diamond grinding is often required making it costly to produce in small quantities. Macor Machinable Glass Ceramic is often a viable alternative that can allows for significantly reduced production costs. The following are some factors to consider when choosing between Macor and Alumina.

Thermal Cycle

Macor is vulnerable to thermal shock – if you have rapid heat up and cool down cycles Macor may not be appropriate. Shapal may be a viable alternative.

Maximum Temperature

Macor has a maximum use temperature of 1000C (unstressed) and 800C (stressed); Alumina does offer higher temperature capabilities.

Wear Resistance

The same feature that makes Macor machinable means that it has relatively poor wear resistance when compared with Alumina.

Cost

For smaller quantities Macor often offers significant price reductions than Alumina components.

-

What is Alumina used for?

Alumina is a very hard ceramic and is excellent at resisting abrasion. It is ideal for wear-resistant inserts or products. Alumina is commonly used as a high temperature electrical insulator, particularly the higher purity grades which offer better resistivity. Alumina also offers good resistance to strong acids and alkalis at elevated temperatures and is ideal for applications where resistance to corrosive substances is required. Some common applications of Alumina include:

- Electronic components & substrates

- High temperature electrical insulators

- High voltage insulators

- Laser tubes

- Machine components

- Mechanical seals

- Precision shafts and axles in high wear environments

- Roller and ball bearings

- Seal rings

- Semiconductor parts

- Shot blast nozzles

- Thermocouple tubes

- Tap plates

- Valve seats

- Wear components

- Wire and thread guides

- Ballistic Armor

-

What are the advantages of Alumina?

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness. Additionally, it can be highly polished making it useful for precision sealing applications like pumps and pistons. Alumina is an excellent high temperature ceramic material due to its high temperature stability. It is the most commonly used type of advanced ceramic and is available in purities ranging from 95 – 99.9%.

Some of the key advantages of Alumina include:

High Temperature Ability – Alumina can be used in both oxidizing and reducing atmospheres up to 1650°C (2900°F) and in vacuum environments up to 2000°C (3600°F).

Abrasion Resistant – Alumina is a very hard ceramic and is excellent at resisting abrasion. It is ideal for wear-resistant inserts or products.

Electrical Insulator – Alumina is commonly used as a high temperature electrical insulator, particularly the higher purity grades which offer better resistivity.

Chemical Resistance – Alumina offers good resistance to strong acids and alkalis at elevated temperatures and is ideal for applications where resistance to corrosive substances is required.

Additional properties and advantages of Alumina include

- High hardness

- Wear & abrasion resistant

- High compressive strength

- High mechanical Strength

- Resists strong acid and alkali attack at high temperatures

- Excellent electrical insulation properties

- Decent thermal conductivity

-

What is the name of Al2O3?

Al2O3 is the chemical formula for Aluminium oxide, which is a chemical compound of aluminium and oxygen. It is commonly called alumina.

-

What's the difference between Zirconia, Alumina, and Zirconia Toughened Alumina (CeramAlloy)?

While Zirconia has the highest fracture toughness of all the oxide monolith ceramic materials, Alumina is one of the most cost effective ceramic materials yet exhibiting very high hardness, thermal stability and favourable electrical properties. CeramAlloy ZTA is a composite material based on Alumina and Zirconia and therefore combining to a certain extent the favourable properties of the two main constituents. So CeramAlloy ZTA will retain the very high hardness of Alumina but also show an increase in fracture toughness and bending strength owing to its Zirconia component so a true “best of both worlds”.