Boron Nitride Ceramic

Material Advantages

To make solid shapes, hexagonal Boron Nitride (hBN) powders and binders are hot-pressed into billets up to 490mm x 490mm x 410mm at pressures up to 2000 psi and temperatures up to 2000°C. This process forms a material that is dense and easily machined and ready to use. It is available in virtually any custom shape that can be machined and has unique characteristics and physical properties which make it valuable for solving tough problems in a wide range of industrial applications.

- Excellent thermal shock resistance

- High electrical resistivity – excluding aerosols, paints, and ZSBN grade

- Low density

- High thermal conductivity

- Anisotropic (thermal conductance differs between parallel and perpendicular planes to pressing direction)

- Corrosion resistant

- Good chemical inertness

- High temperature material

- Non-wetting

- High dielectric breakdown strength, >40 KV/mm

- Low dielectric constant, k=4

- Excellent machinability

Applications

Boron Nitride is known for its exceptional thermal stability and electrical insulation properties. It offers excellent resistance to high temperatures while maintaining outstanding dielectric strength, making it ideal for use in thermal management and electronic applications. Its natural lubricity and low coefficient of friction also make it well-suited for use in high-performance, non-stick and wear-resistant components. Chemically inert and resistant to most molten metals, Boron Nitride performs reliably in extreme environments. Some common applications include:

- Metal and Glass Processing

- Welding, Soldering, Brazing, and Etching

- High Temperature and Furnaces

- Aerospace and Space

- Electronics, Semiconductors, Scientific, and Nuclear

- Coatings, Lubricants, and Fillers

Material Grades

Pure Grades

PCBN1000

General Properties

PCBN1000 is a hot-pressed boron nitride, engineered to work in the most demanding applications. This high purity material is designed to exhibit low thermal expansion while having superb thermal shock properties.

PCBN1000 is easily machinable, has an excellent thermal conductance, very low thermal cycling behavior in use, and has good chemical resistivity to molten metal and glass. The lubricity of the material enables low frictional values even at elevated temperatures. It is also an electrical insulator with high dielectric strength and electrical resistivity.

PCBN1000 is ideal for high temperature applications that require boron nitride with minimal binder. It can be made up to 300mm in diameter and 300mm in length.

Applications

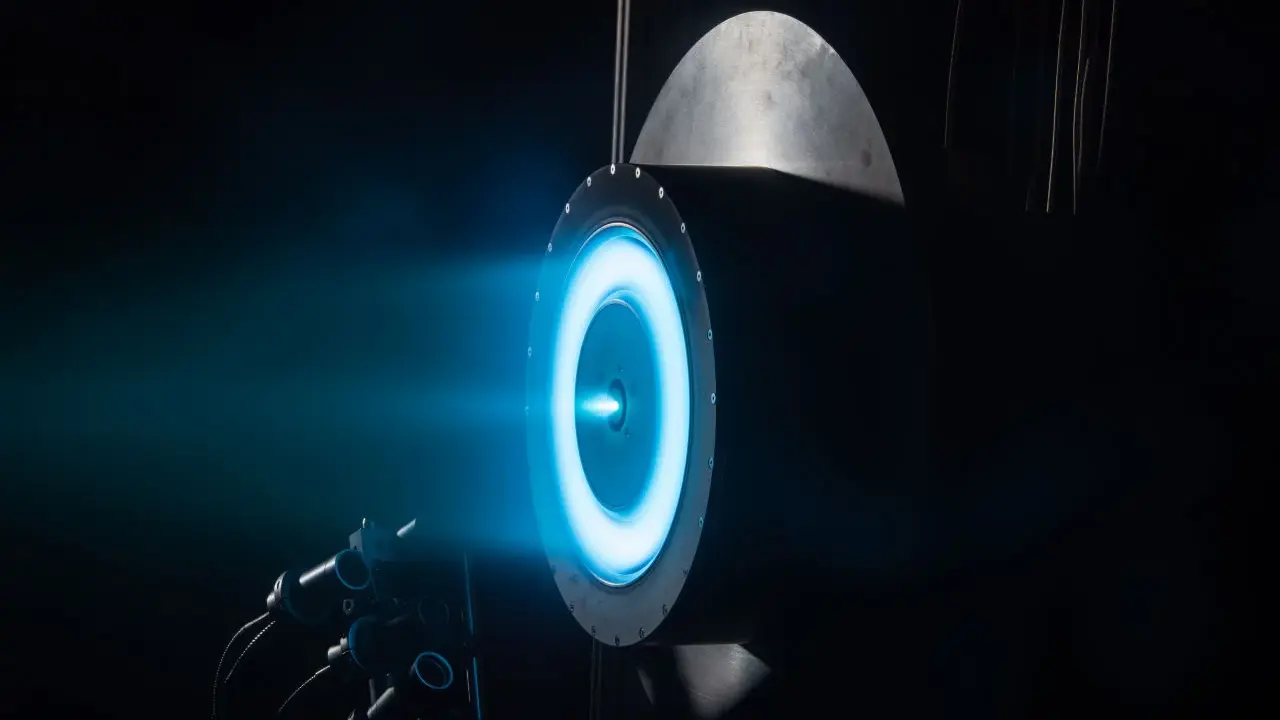

- Electric propulsion discharge channels for Hall Effect Thrusters

- Setter plates for high temperature furnaces

- Crucibles for molten glass and metals

- Electrical insulators for high temperatures and high voltages

- Plasma chamber lining and fittings

- Nozzles for non-ferrous metals and alloys

- Thermocouple protection tubes and sheaths

- Laser supports

PCBN3000

General Properties

PCBN3000 is a unique hot-pressed boron nitride, engineered to work in the most demanding applications. This high purity material exhibits very low thermal expansion with superb thermal shock properties.

Binder-free PCBN3000 is the lowest hardness hexagonal Boron Nitride (hBN). It is easily machinable to very tight tolerances, has excellent thermal conductivity, very low thermal cycling behavior, and good chemical resistivity to molten metals at very high temperatures. The lubricity of the material enables low frictional values. It is non-reactive with graphite and refractory metals in the 2000°C range.

PCBN3000 is also an electrical insulator with high dielectric strength and electrical resistivity at extreme temperatures. PCBN3000 is ideal for high temperature applications that require boron nitride with no binder. It can be machined in large parts from billets up to 490mm x 490mm x 400mm.

Applications

- Setter plates for high temperature furnaces

- Crucibles for non-oxide ceramics, phosphors, and metals

- Electrical insulation for extremely high temperatures and high voltages

- Components exposed to molten salts

- Hall Effect Thruster insulators

- Nozzles for non-ferrous metals and alloys

- Thermocouple protection tubes and sheaths

- Laser supports

PCBN6000

General Properties

PCBN6000 is an isotropic porous pure boron nitride, with high temperature capability, low thermal expansion, good lubrication and thermal shock properties. It is an electrical insulator with high dielectric strength at extreme temperatures. It can be machined into shapes up to 420 x 440 x 100mm.

Applications

- Setter plates for high temperature furnaces

- Crucibles for non-oxide ceramics, phosphors, and metals

- Electrical insulation for extremely high temperatures and high voltages

- Hall Effect Thruster insulators

- Thermocouple protection tubes and sheaths

PCBN11000

General Properties

PCBN11000 is a hot-pressed pure boron nitride, with high temperature capability, very low thermal expansion, good lubrication, and superb thermal shock properties. It is an electrical insulator with high dielectric strength and electrical resistivity at extreme temperatures.

Applications

- Setter plates for high temperature furnaces

- Crucibles for non-oxide ceramics, phosphors, and metals

- Electrical insulation for extremely high temperatures and high voltages

- Hall Effect Thruster insulators

- Thermocouple protection tubes and sheaths

Grade AX05

General Properties

Boron Nitride Grade AX05 is one of the highest purity hexagonal boron nitride (hBN) solids available. It is a good choice for applications where corrosion resistance is more important than wear resistance. It is a diffusion-bonded ceramic and does not depend on B2O3 or other binders for mechanical integrity. Consequently, it is non-wet by almost all molten metals. This ultra purity advantage allows for applications that are not provided by other hot pressed boron nitride solids, such as crucibles for high-purity molten metals. It is commonly used in applications that demand very high thermal conductivity such as nozzles with small orifices.

Key Properties

Chemically

Grade AX05 is extremely inert and non-wet by many molten materials such as metals, glasses, halide salts, and other reagents. The chemical stability allows Grade AX05 to provide a stable, non-reactive material for nozzles, feed-throughs, crucibles, and supports.

Thermally

Grade AX05 has minimal thermal expansion, high thermal conductivity, and use temperature in certain inert atmospheres over 2000°C. Thermal shock stability is excellent over a wide range of use temperatures.

Mechanically

Grade AX05 yields increasing relative strength versus temperature. This important feature provides higher temperature performance to applications previously unattainable with B2O3 and other bonded boron nitrides.

Electrically

Grade AX05 is transparent to microwave energy. It also provides high resistivity and dielectric strength with a low loss tangent and dielectric constant. These characteristics make AX05 an excellent material for high-power low-loss insulators, containers, and fixtures.

Machinability

Grade AX05 can be machined to extremely close tolerances using standard high speed “tool steel” equipment. Machining by grinding may be used if preferred or stringent tolerances are required. Threads can be machined using taps and dies. Cutting oils and coolants should not be used for any reason.

Applications

- High temperature electrical insulators and vacuum furnace supports which require electrical resistivity, high temperature strength, thermal shock resistance, and low chemical reactivity

- Crucibles and containers for high purity molten metals

- lnsulators and source fixtures for ion implantation systems which require high temperature purity and electrical insulation

- Setter plates for the processing of other advanced materials which require stable, inert surfaces

- Nozzles for powdered metal spraying

Binder / Composite Grades

PCBN2000

General Properties

PCBN2000 is a hot-pressed boron nitride/silica composite, delivering excellent dielectric performance and insulation. This material has excellent thermal shock resistance while delivering low thermal expansion.

PCBN2000 is easily machined and has good flexural strength for a boron nitride.

Applications

- Electric propulsion discharge channels for Hall Effect Thrusters

- Plasma/corona insulators

- Plasma constraints in PVD systems

- Wear and corrosion resistance

- Ultra high vacuum insulators

PCBN4000

General Properties

PCBN4000 is a unique hot-pressed boron nitride, engineered to work in the most demanding applications. This stronger and harder Boron Nitride grade exhibits low thermal expansion with superb thermal shock properties.

PCBN4000 is the economical workhorse grade of hexagonal Boron Nitride. It is easily machinable to very tight tolerances, has good thermal conductivity, very low thermal cycling behavior, and chemical resistivity to molten metals to over 1000°C. The lubricity of the material enables low frictional values.

The properties of PCBN4000 are ideal for where the strength of the calcium borate glass binder is needed. It can be machined in large parts from billets up to 490mm x 490mm x 400mm.

PCBN4000 is also an electrical insulator with outstanding properties, retaining high dielectric strength and electrical resistivity up to 1000°C.

Applications

- Setter plates for furnaces

- Crucibles for non-oxide ceramics, phosphors, and metals

- Electrical insulation for high temperatures and high voltages

- Components exposed to molten salts

- Nozzles for non-ferrous metals and alloys

- Thermocouple protection tubes and sheaths

PCBN5000

General Properties

PCBN5000 is a hot-pressed boron nitride, engineered to work in the most demanding applications. It is the combination of properties, along with its machinability, that makes this such a versatile and valuable grade.

This unique grade of hexagonal Boron Nitride (hBN) consists of high purity BN crystals bonded in a silica matrix. This gives it a moisture resistance that other Boron Nitride grades do not possess. It is easily machinable to very tight tolerances.

PCBN5000’s relatively high fracture toughness comes from its ability to deflect crack propagation. In addition, similar to silica glasses, it can exceed its stated temperature range for short periods of time. It won’t thermal shock. And if brought back down, its shape and properties will be maintained. It can be machined in large parts from billets up to 490mm x 490mm x 400mm.

PCBN5000 is also an electrical insulator with outstanding dielectric and microwave properties, retaining high dielectric strength and electrical resistivity up to 1000C.

Applications

- Microwave components

- Electrical insulation for high temperatures and high voltages

- Hall Effect Thruster insulators

PCBN9000

General Properties

Grade PCBN9000 with Calcium Borate binder has good mechanical and thermal properties, low thermal expansion, excellent thermal shock resistance, and strong electrical properties. Grade PCBN9000 is ideal for light metal processing, casting nozzles, PVD coating, and solder pads for example.

Applications

- Electrical insulation for high temperatures

- PVD Frames

- Rada Components

- Setter Plates

- Spaying, Welding Nozzles

Grade A

General Properties

Boron Nitride is an excellent choice for all but the most severe refractory applications. It is a high performance material possessing a glassy B2O3 binder that creates a hard and dense but fully machinable material.

Grade A is the oldest form of hot-pressed Boron Nitride. Specified into applications 50+ years ago, Grade A still finds a substantial replacement business as relatively high-temperature insulators in legacy semiconductor equipment and defense applications. Components up to 410mm x 495mm x 245mm can be produced. However, its B2O3 binder is hygroscopic and care must be taken to ensure components are isolated from moisture during storage and use. Precision Ceramics uses many methods of packaging to maintain the high quality of its machined components.

Applications

- High temperature electrical insulators and vacuum furnace supports which require electrical resistivity, high temperature strength, thermal shock resistance, and low chemical reactivity

- Crucibles and containers for high purity molten metals

- Insulators and source fixtures for ion implantation systems which require high temperature purity and electrical insulation

- Radar components and antenna windows which require exacting electrical and thermal properties

- Setter plates for the processing of other advanced materials which require stable, inert surfaces

- Nozzles for powdered metal spraying

Grade HP

General Properties

Grade HP is the workhorse grade of Boron Nitride. It is useful when low thermal expansion, high thermal shock resistance, and strong electrical properties are required. Grade HP was developed with a calcium borate glass binder in order to minimize the moisture issues of Grade A. It is available in sizes up to 410mm x 495mm x 245mm. It finds many diverse applications with its excellent machinability and maximum use temperature over 1000°C in inert or vacuum atmospheres.

Boron Nitride Grade HP is a superior solid grade for formulations of less than 1000°C. Additionally, Grade HP has ten times the moisture resistance of Grade A. It is commonly used for many light metal applications such as Al, Ti, Mg, and Zn.

Key Properties

Chemically

Grade HP has high corrosion resistance due to the addition of boron nitride. It has ten times the moisture resistance of other boron nitride solids due to the addition of calcium, which combines with boric oxide to form calcium borate.

Thermally

Excellent thermal shock resistance and conductivity – commonly used in many light metal applications such as Al, Ti, Mg, and Zn.

Electrically

Low dielectric constant material – also commonly used in many high temperature insulators.

Machinability

Like other grades of Boron Nitride, Grade HP can be machined using standard high speed ‘tool steel’ equipment. Machining by grinding may be used if preferred or stringent tolerances are required.

Applications

- High temperature electrical insulators and vacuum furnace supports which require electrical resistivity, high temperature strength, thermal shock resistance, and low chemical reactivity

- Crucibles and containers for high purity molten metals

- Insulators and source fixtures for ion implantation systems which require high temperature purity and electrical insulation

- Radar components and antenna windows which require stringent electrical and thermal properties

- Setter plates for the processing of other advanced materials which require stable, inert surfaces

- Nozzles for powdered metal spraying

Grade M/M26

General Properties

Solid Boron Nitride Grade M/M26 is a hydrophobic advanced ceramic. Composed of boron nitride and silica, it is completely resistant to moisture. This grade has successfully passed MIL-I-10A grade of L542 test, which is a procedure requiring immersion in water for 48 hours prior to testing at elevated frequencies. Grade M/M26 is suitable for the most severe electrical applications. It is an excellent refractory material at temperatures up to 1400°C and is unparalleled in resistance to thermal shock.

Applications

- High temperature electrical insulators and vacuum furnace supports which require electrical resistivity, high temperature strength, thermal shock resistance, and low chemical resistivity

- Crucibles and containers for high purity molten metals

- Tools and refractories for glass forming which provide non-wetting, non-B2O3 containing contacts

- Radar components and antenna windows which require exacting electrical and thermal properties

Mechanical Grades

PCBN7000

General Properties

Grade PCBN7000 combines the thermal performance and machinability of hot-pressed boron nitride with the strength and toughness of Zirconia. Its properties make it ideal for molten metal applications, also offering mechanical durability and superior electrical insulation.

Applications

- Break Rings

- Crucibles & Containers

- Jigs

- High temperature bearings

- High temperature valves

- Molds

- Nozzles

- Heat treatment fixtures

PCBN8000

General Properties

Grade PCBN8000 combines the thermal performance and machinability of hot-pressed boron nitride with the strength and toughness of Silicon Nitride. Its properties make it ideal for molten metal applications, also offering mechanical durability and superior electrical insulation.

Applications

- Break Rings

- Crucibles & Containers

- Jigs

- High temperature bearings

- High temperature valves

- Molds

- Nozzles

- Heat treatment fixtures

Grade ZSBN

General Properties

Grade ZSBN boron nitride is a composite material combining the best thermal performance and machinability characteristics of hot-pressed boron nitride with the strength, wear-resistance, and non-reactivity of silicon carbide and zirconia. It was developed for demanding applications requiring the combination of thermal conductivity, high wear resistance, and corrosion resistance.

Originally developed for break rings for horizontal continuous casters, its unique thermal, chemical, electrical, wear, and machinability properties permit a wide variety of molten metal contact applications. Hexagonal Boron Nitride (hBN) is an inherently soft material. However, with ZSBN’s hard zirconia particles evenly dispersed with boron nitride platelets in the hard borosilicate glass matrix, it has great wear-resistant properties in addition to the inherent non-wetting aspects of the hBN.

ZSBN is a uniquely high-performing solid that is especially suited for molten metal applications such as continuous casting break rings, where wear-resistance and thermal conductivity are essential. Other applications include molten metal atomizing nozzles, glass contact wear components, and countless guides and rollers in diverse light metal baths of Zn, Mg, Al, and Li.

Key Properties

Chemically

Unparalleled resistance to molten metal wetting due to boron nitride content.

Thermally

Excellent high temperature operation and thermal shock resistance.

Mechanically

Excellent wear-resistance and increased strength from zirconia and a small amount of silicon carbide. Remarkable corrosion-resistance over a wide range of temperatures.

Machinability

Grade ZSBN is easily machined, even to complex shapes and forms, quickly and inexpensively. Machining tolerances of 0.002” or better are achievable.

Applications

- Break rings for continuous casting of metals

- Components

- Crucibles

- Deck plates

- Heat treatment fixtures

- High temperature bearings

- High temperature mechanical components

- High temperature valves

- Jigs

- Molds

- Molten metal and glass castings

- Muffles

- Nozzles for transfer or atomization

- Side dams

- Spacers

Material Properties

Mechanical Properties

| Pure Grades | Binder / Composite Grades | Mechanical Grades | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Property | Unit | PCBN1000 | PCBN3000 | PCBN6000 | PCBN11000 | Grade AX05 | PCBN2000 | PCBN4000 | PCBN5000 | PCBN9000 | Grade A | Grade HP | Grade M26 | PCBN7000 | PCBN8000 | Grade ZSBN |

| Density | g/cm3 | 1.9 | 1.9 | 1.6 | 1.9 | 1.9 | 2.1 | 1.85-2.05 | 2.0 | 1.9 | 2.0 | 2.0 | 2.1 | 2.9 | 2.3 | 2.9 |

| Compressive Strength | MPa | 40 ∥ / 40 ⊥ | 24 ∥ | – | 22 ∥ / 23 ⊥ | 25 ∥ | 312 ∥ / 312 ⊥ | 95 ∥ | – | 52 ∥ / 60 ⊥ | 143 ∥ / 186 ⊥ | 96 ∥ | – | 170 ∥ / 170 ⊥ | 270 ∥ / 315 ⊥ | 219 ∥ / 254 ⊥ |

| Flexural Strength | MPa | 13 ∥ / 29 ⊥ | 21 ∥ / 20 ⊥ | 28 | 10 ∥ / 8 ⊥ | 22 ∥ / 21 ⊥ | >49 ∥ / 49 ⊥ | 58 ∥ / 44 ⊥ | 61 ∥ / 33 ⊥ | 45 ∥ / 35 ⊥ | 94 ∥ / 65 ⊥ | 59 ∥ / 45 ⊥ | 62 ∥ / 34 ⊥ | 120 ∥ / 80 ⊥ | 120 ∥ / 95 ⊥ | 144 ∥ / 107 ⊥ |

| Young’s Modulus | GPa | – | 45 ∥ / 73 ⊥ | 12 | 23 ∥ / 20 ⊥ | 17 ∥ / 71 ⊥ | – | 39 ∥ / 58 ⊥ | – | 30 ∥ / 25 ⊥ | 47 ∥ / 74 ⊥ | 40 ∥ / 60 ⊥ | – | 45 ∥ / 30 ⊥ | 45 ∥ / 30 ⊥ | 71 ∥ / 71 ⊥ |

Note: ∥ = Parallel and ⊥ = Perpendicular

Note: ∥ = Parallel and ⊥ = Perpendicular

Thermal Properties

| Pure Grades | Binder / Composite Grades | Mechanical Grades | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Property | Unit | PCBN1000 | PCBN3000 | PCBN6000 | PCBN11000 | Grade AX05 | PCBN2000 | PCBN4000 | PCBN5000 | PCBN9000 | Grade A | Grade HP | Grade M26 | PCBN7000 | PCBN8000 | Grade ZSBN |

| Thermal Conductivity | W/mK | 21 ∥ / 21 ⊥ | 73 ∥ / 128 ⊥ | 60 | 20 ∥ / 30 ⊥ | 78 ∥ / 130 ⊥ | – | 27 ∥ / 29 ⊥ | 11 ∥ / 26 ⊥ | 33 ∥ / 35 ⊥ | 30 ∥ / 34 ⊥ | 27 ∥ / 29 ⊥ | 11 ∥ / 29 ⊥ | 28 ∥ / 38 ⊥ | 27 ∥ / 45 ⊥ | 24 ∥ / 34 ⊥ |

| Max Temp (Oxidizing) 1 | °C | 850 | 850 | 850 | 900 | 850 | 850 | 850 | 1000 | 900 | 850 | 850 | 1000+ | 900 | 900 | 850 |

| Max Temp (Inert) 1 | °C | 2000 | 2000 | 2100 | 2000 | 2000 | 1000 | 1200 | 1000 | 1500 | 1200 | 1150 | 1000+ | 1800 | 1800 | 1600 |

| CTE2 25°C ➞ 400°C | 10-6/K | – | -2.3 ∥ / -0.7 ⊥ | -0.6 | 1.0 ∥ / 0.5 ⊥ | -2.3 ∥ / -0.7 ⊥ | – | 0.6 ∥ / 0.4 ⊥ | 3.0 ∥ / 0.4 ⊥ | 4.0 ∥ / 3.0 ⊥ | 3.0 ∥ / 3.0 ⊥ | 0.6 ∥ / 0.4 ⊥ | 3.0 ∥ / 0.4 ⊥ | 8.0 ∥ / 4.0 ⊥ | 4.6 ∥ / 2.5 ⊥ | 4.1 ∥ / 3.4 ⊥ |

| CTE2 400°C ➞ 800°C | 10-6/K | – | -2.5 ∥ / 1.1 ⊥ | – | – | -2.5 ∥ / 1.1 ⊥ | – | 1.1 ∥ / 0.8 ⊥ | 5.6 ∥ / 4.3 ⊥ | – | 2.0 ∥ / 1.4 ⊥ | 1.1 ∥ / 0.8 ⊥ | 2.5 ∥ / 0.1 ⊥ | – | – | 5.6 ∥ / 4.3 ⊥ |

| CTE2 800°C ➞ 1200°C | 10-6/K | – | 1.6 ∥ / 0.4 ⊥ | – | – | 1.6 ∥ / 0.4 ⊥ | – | 1.5 ∥ / 0.9 ⊥ | 7.2 ∥ / 5.2 ⊥ | – | 1.9 ∥ / 1.8 ⊥ | 1.5 ∥ / 0.9 ⊥ | 3.0 ∥ / 0.1 ⊥ | – | – | 7.2 ∥ / 5.2 ⊥ |

| CTE2 1200°C ➞ 1600°C | 10-6/K | – | 0.9 ∥ / 0.3 ⊥ | – | – | 0.9 ∥ / 0.3 ⊥ | – | 2.8 ∥ / 2.7 ⊥ | 4.6 ∥ / 3.4 ⊥ | – | 5.0 ∥ / 4.8 ⊥ | 2.8 ∥ / 2.7 ⊥ | – | – | – | 4.6 ∥ / 3.4 ⊥ |

| CTE2 1600°C ➞ 1900°C | 10-6/K | – | 0.5 ∥ / 0.9 ⊥ | – | – | 0.5 ∥ / 0.9 ⊥ | – | – | – | – | 7.2 ∥ / 6.1 ⊥ | – | – | – | – | – |

| CTE2 25°C ➞ 1000°C | 10-6/K | 5.5 ∥ / 1 ⊥ | – | – | – | – | 2.5 ∥ / 2.0 ⊥ | – | – | – | – | – | – | – | – | – |

1 No load

2 Coefficient of Thermal Expansion (CTE) describes how the size of component changes with temperature.

Electrical Properties

| Pure Grades | Binder / Composite Grades | Mechanical Grades | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Property | Unit | PCBN1000 | PCBN3000 | PCBN6000 | PCBN11000 | Grade AX05 | PCBN2000 | PCBN4000 | PCBN5000 | PCBN9000 | Grade A | Grade HP | Grade M26 | PCBN7000 | PCBN8000 | Grade ZSBN |

| Dielectric Strength | kV/mm | >40 | >40 | >40 | 63 | 79 | – | >40 | >40 | 100 | 88 | >10 | 66 | – | 100 | 3.5 |

| Dielectric Constant | 1 MHz | – | 4.0 ∥ / 4.0 ⊥ | 4.9 | – | 4.0 ∥ / 4.0 ⊥ | – | 4.3 ∥ / 4.0 ⊥ | 4.5 ∥ / 3.8 ⊥ | – | 4.6 ∥ / 4.2 ⊥ | 4.3 ∥ / 4.0 ⊥ | 4.5 ∥ / 3.8 ⊥ | – | – | 18 ∥ / 19 ⊥ |

| Dissipation Factor | 1 MHz | – | 1.2E-3 ∥ / 3.0E -4 ⊥ | 1.0E -3 | – | 1.2E-3 ∥ / 3.0E-3 ⊥ | – | 1.5E -3 ∥ / 2.1E -3 ⊥ | 1.7E -3 ∥ / 6.7E -3 ⊥ | – | 1.2E-3 ∥ / 3.4E-3 ⊥ | 1.5E-3 ∥ / 2.1E-3 ⊥ | 1.7E-3 ∥ / 6.7E-3 ⊥ | – | – | 4.5E-2 ∥ / 6.7E-2 ⊥ |

| Volume Resistivity @25°C | ohm-cm | >1014 / 1014 ⊥ | >1013 ∥ / 1014 ⊥ | 1015 | >1015 | >1013 ∥ / 1014 ⊥ | – | >1013 ∥ / 1013 ⊥ | >1013 ∥ / 1014 ⊥ | >1015 ∥ / 1015 ⊥ | >1013 ∥ / 1014 ⊥ | >1013 ∥ / 1013 ⊥ | >1013 ∥ / 1014 ⊥ | >1012 ∥ / 1012 ⊥ | >1015 ∥ / 1015 ⊥ | >1013 ∥ / 1012 ⊥ |

Disclaimer: The values presented are mean and typical of those resulted from test samples. They are provided as an indication only to serve as guidance in the design of ceramic components and are not guaranteed in any way. The actual values can vary according to the shape and size of the envisioned component.

Datasheets

All Grades

Boron Nitride

All Grades

Pure Grades

Boron Nitride

PCBN1000

Boron Nitride

PCBN3000

Boron Nitride

PCBN6000

Boron Nitride

PCBN11000

Boron Nitride

Grade AX05

Binder / Composite Grades

Boron Nitride

PCBN2000

Boron Nitride

Grade HP

Boron Nitride

PCBN4000

Boron Nitride

Grade M & M26

Boron Nitride

PCBN5000

Boron Nitride

PCBN9000

Boron Nitride

Grade A

Mechanical Grades

Boron Nitride

PCBN7000

Boron Nitride

PCBN8000

Boron Nitride

Grade ZSBN

Boron Nitride Machining

The accompanying video shows the milling of Boron Nitride Grade HP Ceramic into finished component with a Robodrill Machining Centre and fitted with probe system.

Precision Ceramics is your Boron Nitride machining specialist for your technical ceramic prototyping and manufacturing needs. We are always happy to provide advice on materials, design, and application. If you would like to buy Boron Nitride plates, bars, rods, tubes, Aerosol Sprays, Paintable Coatings, Industrial Powders, or custom machined parts, please contact us and one of our experts will be happy to assist you.

Frequently Asked Questions

-

What is Boron Nitride used for?

Boron Nitride is available in virtually any custom shape that can be machined and has unique characteristics and physical properties which make it valuable for solving tough problems in a wide range of industrial applications.

- Break rings for continuous casting of metals

- Crucibles and containers for high purity molten metals and glasses

- Deck plates

- Heat treatment fixtures

- High temperature lubricant

- High temperature valves

- High temperature and high voltage electrical insulators

- Induction heating coil supports

- Laser Nozzles

- Mold release agent

- Moltel metals and glass casting

- Nozzles for transfer or atomization

- Nuclear Shielding

- Radar components and antenna windows

- Refractory applications

- Spacers

- Vacuum furnace supports which require electrical resistivity

- Setter plates for high temperature furnaces

- Electrical insulators for high temperatures and high voltages

- Vacuum feedthroughs

- Plasma chamber lining and fittings

- Nozzles for non-ferrous metals and alloys

- Thermocouple protection tubes and sheaths

- Laser supports

-

What is Boron Nitride?

Boron Nitride (BN) is an advanced synthetic ceramic material available in solid and powder form. Its unique properties – from high heat capacity and outstanding thermal conductivity to easy machinability, lubricity, low dielectric constant and superior dielectric strength – make boron nitride a truly outstanding material.

In its solid form, boron nitride is often referred to as “white graphite” because it has a microstructure similar to that of graphite. However, unlike graphite, boron nitride is an excellent electrical insulator that has a higher oxidation temperature. It offers high thermal conductivity and good thermal shock resistance and can be easily machined to close tolerances in virtually any shape. After machining, it is ready for use without additional heat treating or firing operations.

In inert and reducing atmospheres, our Boron Nitride grades will withstand temperatures over 2000°C. It is commonly used as an insulator in contact with tungsten and graphite electrodes at those temperatures.

-

What forms are Boron Nitride available in?

Boron Nitride (BN) is available in solid, powder, liquid, and aerosol form.

In its solid form, boron nitride is often referred to as “white graphite” because it has a microstructure similar to that of graphite. Large billets of hot pressed material are available to produce large complex components. The material is easy machining and requires no post heat treatment.

Precision Ceramics offer a limited range of powders for lubrication and thermal management.

Boron nitride can be used in a liquid suspension suitable for painting on surfaces in contact with materials such as molten aluminium.

It can also be supplied in an aerosol for easy application and is used in glass manufacturing and for working materials such as titanium.

Precision Ceramics offer a wide range of solid boron nitrides suitable for many applications and we can discuss the best option to suit your requirements. We can supply the material or finished machined components to your drawing specifications.

-

What is the difference between Wurtzite, Cubic, and Hexagonal Boron Nitride?

Wurtzite boron nitride has been found in small quantities on meteors that have landed on earth and is not commercially available. Initial investigation of the wurtzite form suggested it was potentially 18% stronger than diamond. But as only small quantities have been found, verification of this has not been able to be conclusively proved.

Cubic boron nitride has a crystal structure similar to that of diamond with similar properties. Cubic boron nitride is commercially available and is used in applications to replace diamond. It’s hardness is its key property.

Hexagonal boron nitride is readily commercially available. In solid form, it can be made in large billets. The solid material can withstand high temperatures whilst having good electrical properties and withstand aggressive molten metals. Unlike the wurtzite and cubic forms, the material is relatively soft.

Precision Ceramics has over 30 years of experience working with hexagonal forms of boron nitride available in various grades.